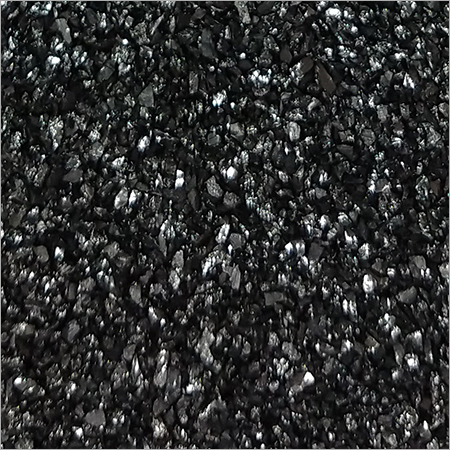

Anthracite 90

Price 75 INR/ Tonne

MOQ : 10 Kilograms, ,

Anthracite 90 Specification

- Surface Finish

- Smooth, granular

- Form

- Granules

- Water Absorption

- <2%

- Chemical Composition

- Fixed Carbon 90% min, Ash 8-10%, Volatile Matter 1.5% max, Moisture 1-2%

- Purity(%)

- 90% min

- Application

- Water filtration, industrial applications

- Usage & Applications

- Filtration media, water purification, industrial filtration

- Density

- 950 Gram per cubic centimeter(g/cm3)

- Melting Point

- > 1200C

- Hardness (%)

- >95%

- Product Type

- Anthracite

- Shape

- Granular

- Porosity

- Low

- Dimensional Stability

- Excellent at high temperatures

- Strength

- High crushing strength

- Specific Gravity

- 1.6 g/cm

- Thermal Conductivity

- Low

- Color

- Black grey

About Anthracite 90

Anthracite 90 is premium grade anthracite with carbon content +90%. Anthracite filter media promotes higher service flow rates and longer filter runs. Backwash rates are reduced as well. Low uniformity coefficient anthracite filter media extends the life of your filter, typically produces consistent improvements in turbidity removal, due in part to more efficient solids loading. Also, low uniformity coefficient media produces smaller changes in effluent turbidity during periods of peak influent turbidity.

Advantages

Advantages

- High carbon content in top quality anthracite

- Low specific gravity reduces backwash rates and energy consumption

- Angular particles for low head loss and high filtration capacity

- Increased plant capacity by the use of higher filtration rates

- Appearance : Black sharp angular grains

- Carbon Content: Min 90%

- Bulk Density: 750 - 850 Kg/ m

- Hardness: 3.00- 3.25 (Mohs scale)

- Specific Gravity: 1.4 1.6

- Uniformity Coefficient: 1.3- 1.5

- Ash Content: 7%

- Moisture Content: 1.5-2.0%

- Volatile Matter: Max 5%

- 0.85 mm 1.7 mm

- 1.5 mm 2 mm

- 1.2 mm 2.4 mm

Superior Filtration Efficiency

Anthracite 90 excels as a granular filtration media, thanks to its low volatile matter and moisture, which contribute to effective removal of impurities from water. With a hardness greater than 95% and high-dimensional stability even at elevated temperatures, it guarantees long-term, consistent filtration results for municipal, industrial, and private water treatment systems.

Quality and Durability for Industrial Needs

With its high fixed carbon content and strong resistance to crushing and swelling, Anthracite 90 offers outstanding durability under heavy-duty operations. Its uniform, coarse granules ensure reliable performance in various industrial filtration processes, including chemical, power generation, and manufacturing sectors. The smooth surface facilitates easy flow and reduces clogging during use.

FAQs of Anthracite 90:

Q: How is Anthracite 90 used in water filtration and industrial applications?

A: Anthracite 90 is primarily used as a granular filter media in water purification systems. Its coarse granules trap suspended solids while allowing water to flow through efficiently. In industrial settings, it serves as a robust filtration agent in processes that require high mechanical strength and heat resistance.Q: What are the main benefits of using Anthracite 90 for filtration?

A: Anthracite 90 offers excellent filtration efficiency due to its stable structure, high fixed carbon content, and low ash and volatile matter. Its high crushing strength and dimensional stability make it suitable for continuous use in demanding water and industrial filtration operations.Q: When should I choose Anthracite 90 over other filtration media?

A: Anthracite 90 is ideal when you need a coarse and durable filtration media that can withstand high temperatures and prolonged use without degrading. It is particularly beneficial in systems that require low water absorption, low porosity, and a high degree of mechanical strength.Q: Where can Anthracite 90 be sourced or supplied from?

A: Anthracite 90 is available through multiple channels including manufacturers, exporters, dealers, traders, suppliers, and wholesalers across India. It is commonly supplied in 25 or 50 kg polypropylene (PP) bags for convenient transport and storage.Q: What is the recommended process for incorporating Anthracite 90 in filtration systems?

A: To use Anthracite 90, layer it appropriately in the filtration unit according to system design specifications. The granules should be thoroughly rinsed before initial use to remove fine particles, and then placed above or between other media as required for multi-layer filtration setups.Q: Can Anthracite 90 withstand high-temperature industrial processes?

A: Yes, thanks to its melting point over 1200C and high crushing strength, Anthracite 90 remains stable and maintains its filtration properties in high-temperature environments typically found in industrial sectors.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry